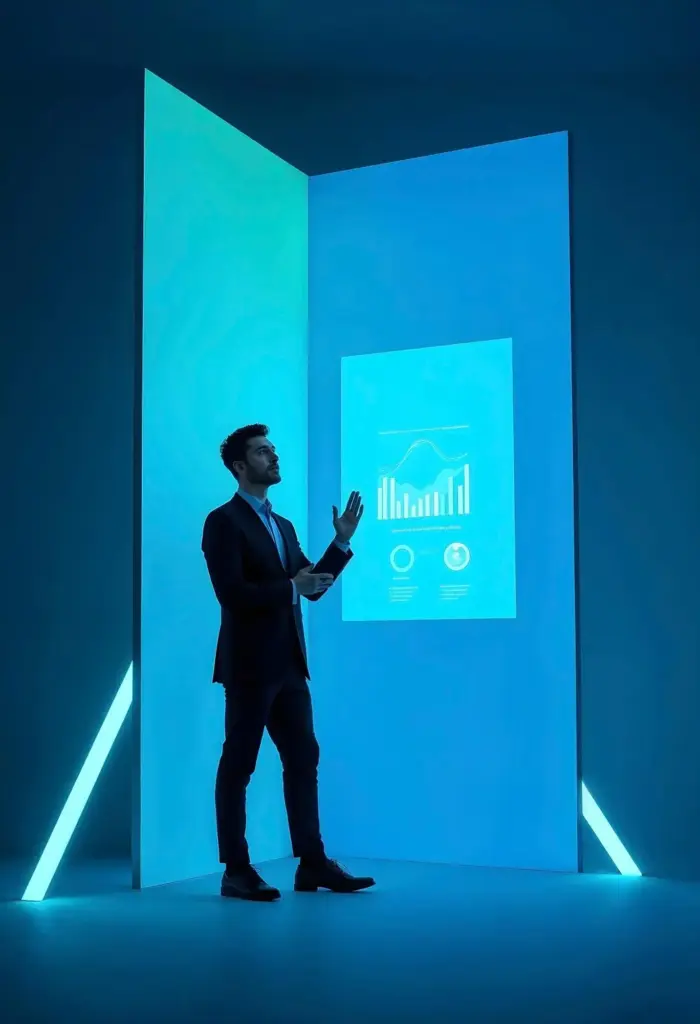

From Process to Profit: Dashboards That Drive Decisions

Trace the Money Trail Through Operations

Choose KPIs That Predict Cash, Not Just Describe Activity

Leading vs. Lagging, Simplified

Right-Sized for Small Teams

Design Dashboards People Use Every Day

Build a Lightweight Data Pipeline Without Drama

Start Manual, Automate Later

Define a Single Source of Truth

Audit, Log, and Recover

Turn Reviews Into Rituals That Change Outcomes

Stories From the Field: Three Mini Wins

01

Neighborhood Café Boosts Throughput

A local café tracked order-to-serve time, first-pass accuracy, and average ticket. By rearranging prep stations and pre-portioning during off-peak hours, cycle time fell by twenty percent, enabling two extra rush-hour orders per fifteen minutes. Average ticket rose as staff felt less rushed, improving upsell consistency. The dashboard forecasted weekly contribution gains, which matched actuals within five percent, funding a new espresso grinder without debt.

02

E-Commerce Boutique Slashes Stockouts

A small online retailer highlighted pick-pack cycle time, out-of-stock percentage, and refund rate. A simple reorder-point rule based on seven-day velocity and supplier lead time stabilized availability. Cycle time improvements freed capacity to verify shipments proactively. Stockouts dropped by thirty percent, refunds declined, and repeat purchase rose, lifting contribution margin. The team now shares a weekly snapshot with subscribers; reply with your biggest fulfillment challenge to compare notes.

03

Service Contractor Raises First-Time Fix Rate

A home services company tracked first-time fix rate, parts readiness, and travel variance. Technicians received pre-visit checklists and part kits. First-time fixes climbed twelve points, reducing repeat visits and fuel costs. Customer reviews improved, increasing referral volume without extra ad spend. The dashboard showed savings per route, helping the owner adjust pricing confidently. Want the checklist template? Subscribe and comment “FTF” to receive the lightweight starter kit promptly.

All Rights Reserved.